You can have a recurring event, but you can’t introduce the same idea twice. For this years community print at 3D meet-up Sweden 2020 we are going bigger and more complex by introducing a new element into the construction: wood.

To sign up for the event follow the follow link: https://3dmeetup.se/community-print/

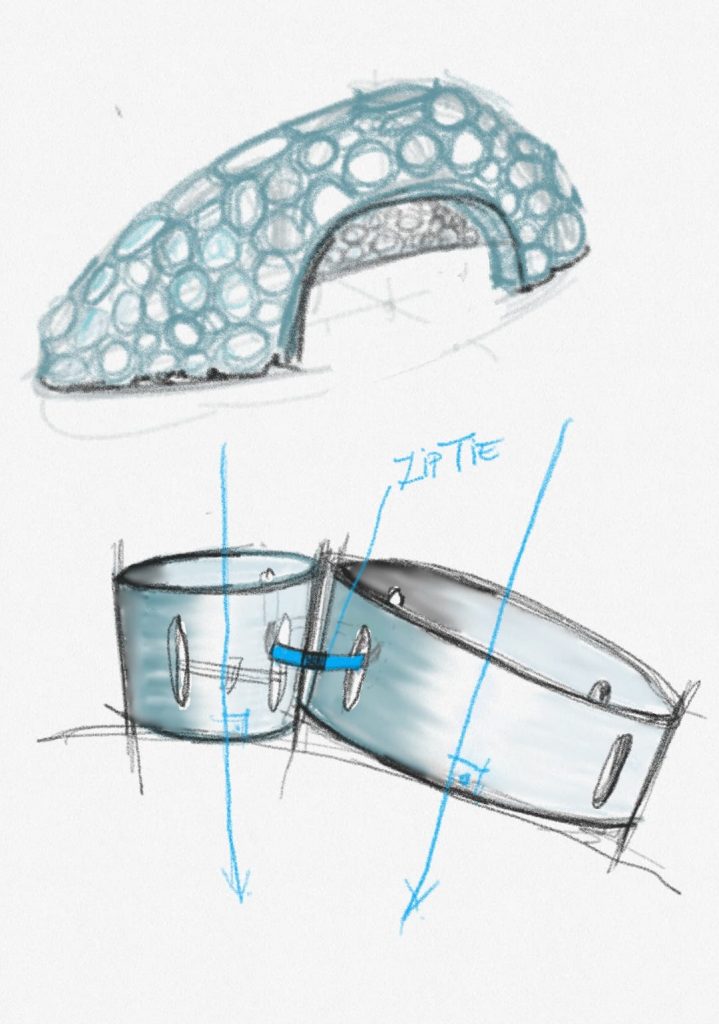

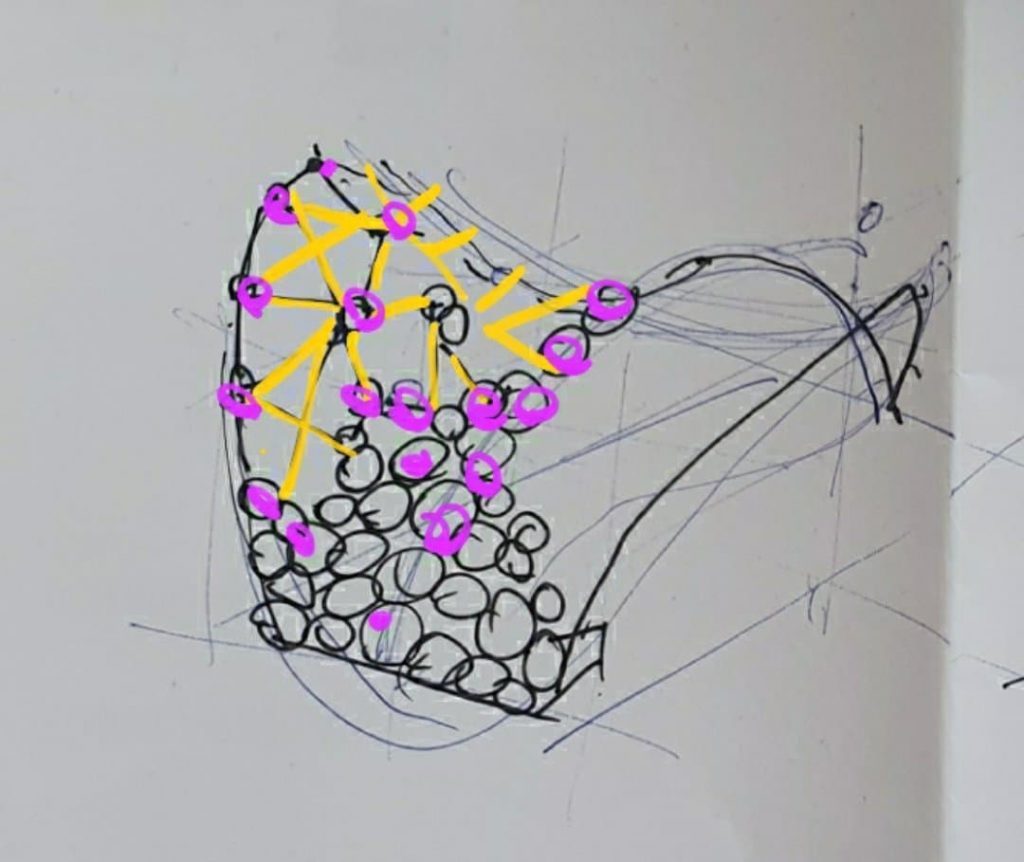

To prove that the plans you make early on rarely see completion, in this case due to the fact that it didn’t fit the surroundings and layout, here is how the pavilion was initially conceptualize:

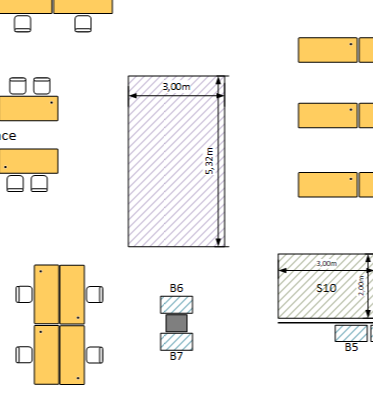

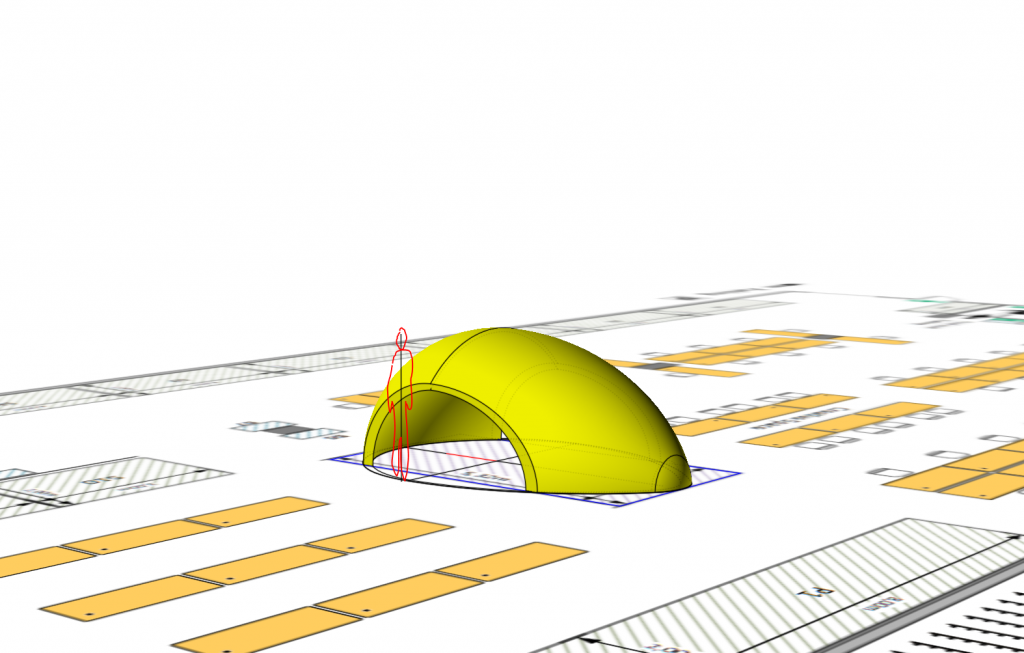

However the reality started to hit when I got the space allocated and had to drop the original design due to the space allocated within the event as you can see in the image below.

With a surface of 5×3 m the height of the original design would have been half of the width, restricting us to 1.5 meters.

You can see there the issue was, so the concept was scratched and a new system had to be found. As I was stressing arround the kitchen on a saturday morning of what to do and how to do it, I got the question:

” S: you already did a fully 3D printed pavillion, why don’t you do something else?

Me: Like what?

S: Like adding wood.

Me: How does one even begin to deal with the logistic, what kind of wood can I use?

S: Lets go to Bauhaus! You will see!”

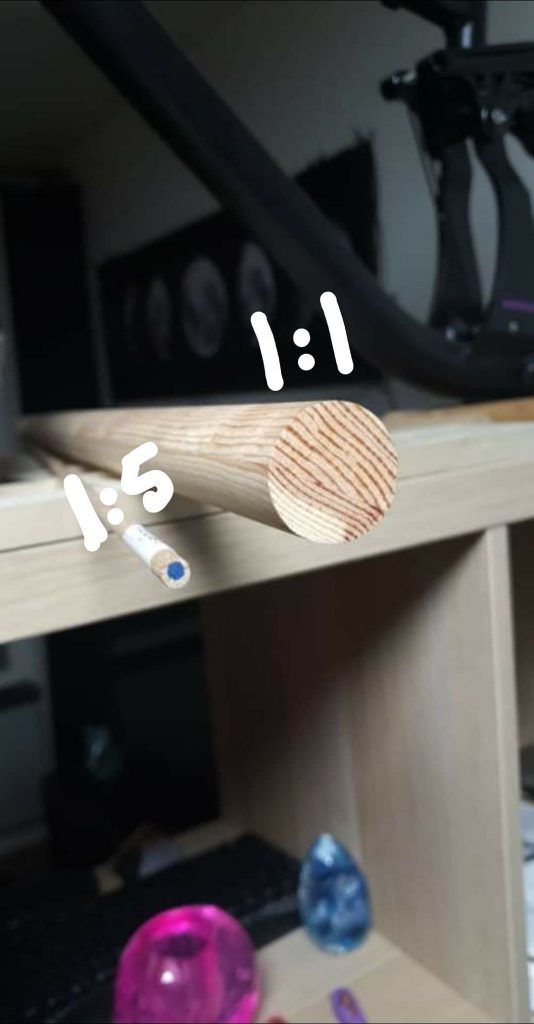

And I did see , before the schetch was even done I bought some prototype wooden bars to have in the house. I wanted something that could be use both for the full scale and small scale – so later on I can build a small scale pavillion.

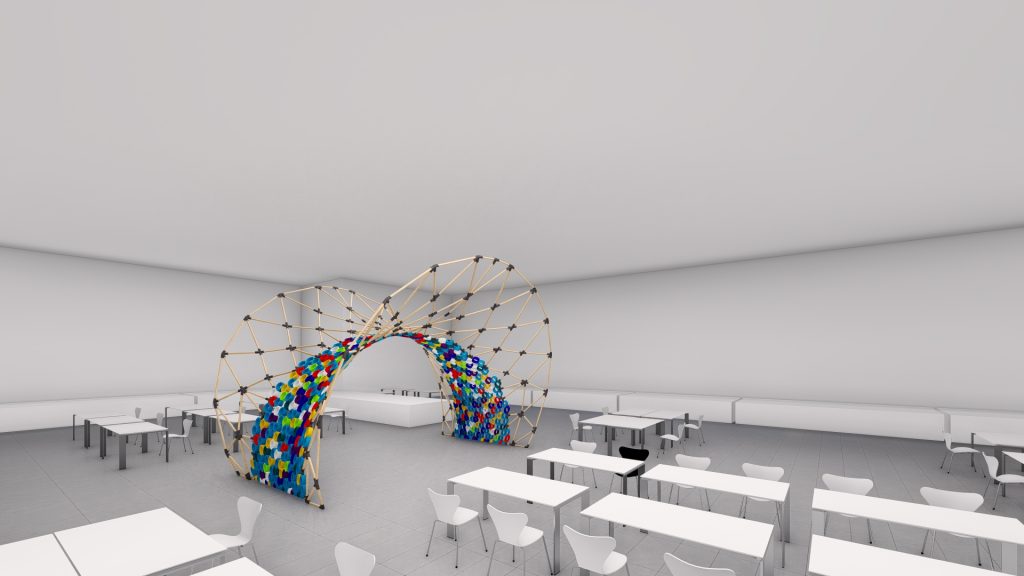

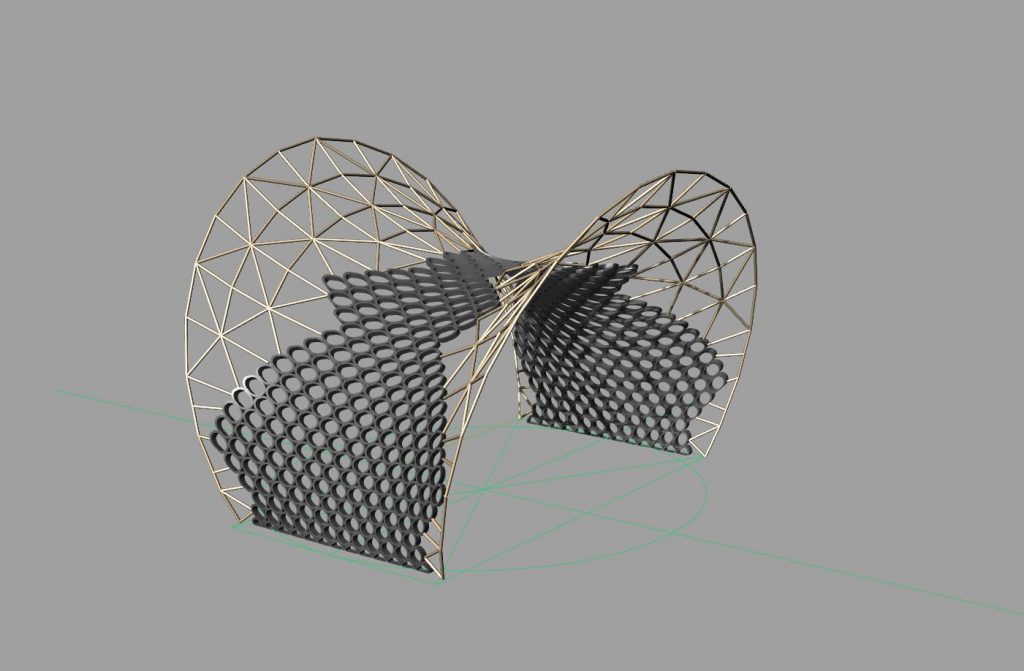

With 400 pieces available to download and 140 joints to connect the wood the project was on it’s way!

As a sign of good luck I claimed the first 6 parts and decided to take upon myself the printing of the 140 joints. Luckly another maker – Tommie E. has a printer that is too small for the pieces left for claiming. Therefore being restricted to 140×140 mm – so he helped me out by printing our the joints.

I will keep updating the rest of the infirmation as soon as I have more time – right now my attention is on completing the Community Print – The Halo Pavilion.

Lots of Love&Unicorns,

Stefania D.